PRODUCTS

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubator, Air-jacket (Standard, IB4-AS)

- Incubator, Air-jacket (Advanced, IB4-AV)

- Incubator, Forced Convection (Standard, IB4-S)

- Incubator, Forced Convection (Advanced, IB4-V)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Natural Convection Oven (Standard, ON4-S)

- Natural Convection Oven (Advanced, ON4-V)

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Vertical Electrophoresis System

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Industrial Test Equipment

- HOME

- > PRODUCTS

- > Industrial Test Equipment

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubator, Air-jacket (Standard, IB4-AS)

- Incubator, Air-jacket (Advanced, IB4-AV)

- Incubator, Forced Convection (Standard, IB4-S)

- Incubator, Forced Convection (Advanced, IB4-V)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Natural Convection Oven (Standard, ON4-S)

- Natural Convection Oven (Advanced, ON4-V)

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Vertical Electrophoresis System

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Heating & Cooling Chambers (KMV)

Temperature values of all chambers are measured according to DIN 12880 and IEC 60068-3-5.

Model Name : KMV-012/025/040/070/100

* K - SERIES

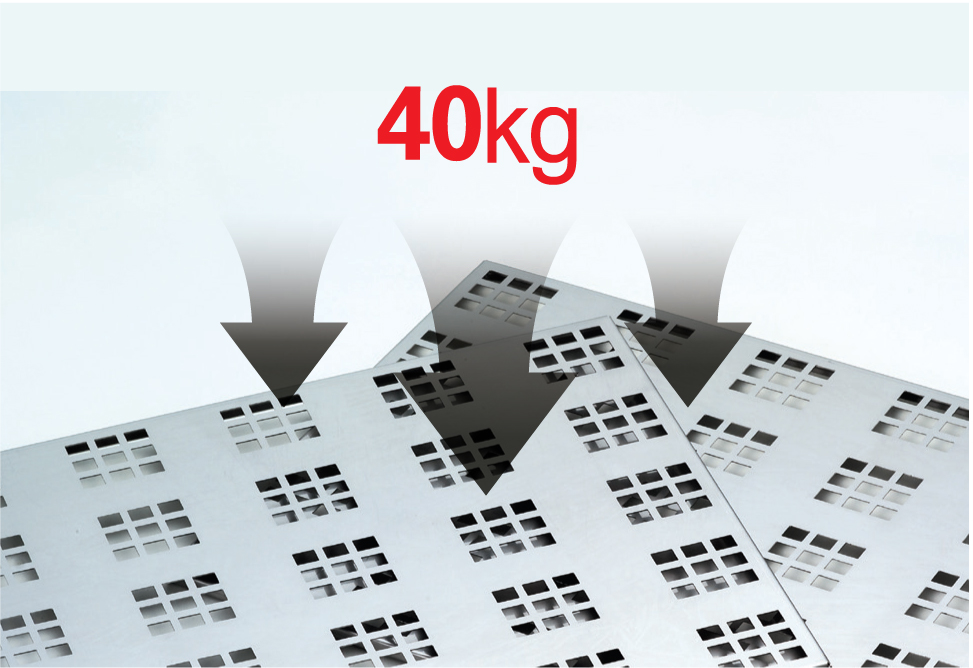

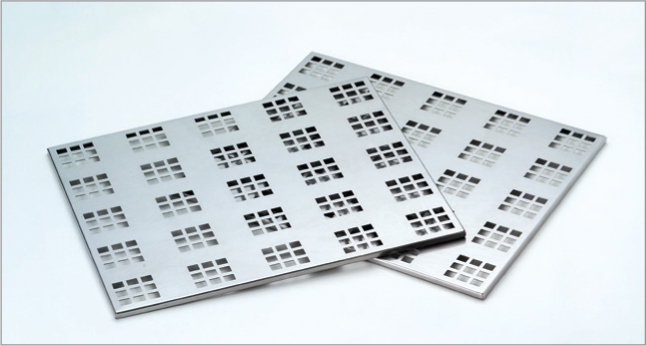

Perforated shelves for heavy load (optional)

Stainless steel chamber

Two-point door latch

Individual over temperature limiter

Warning signal lamp (optional)

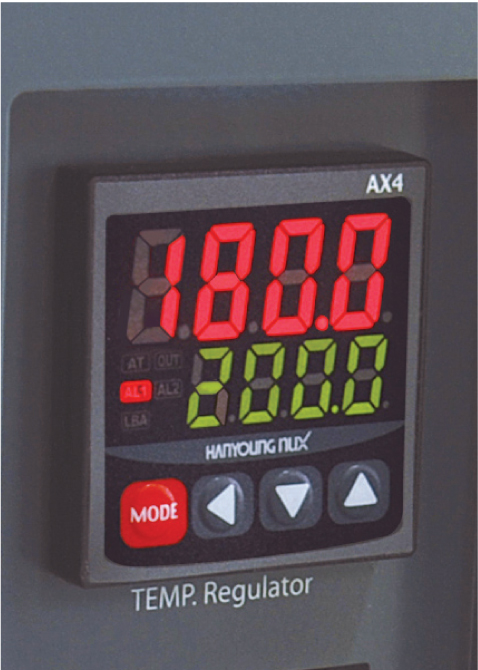

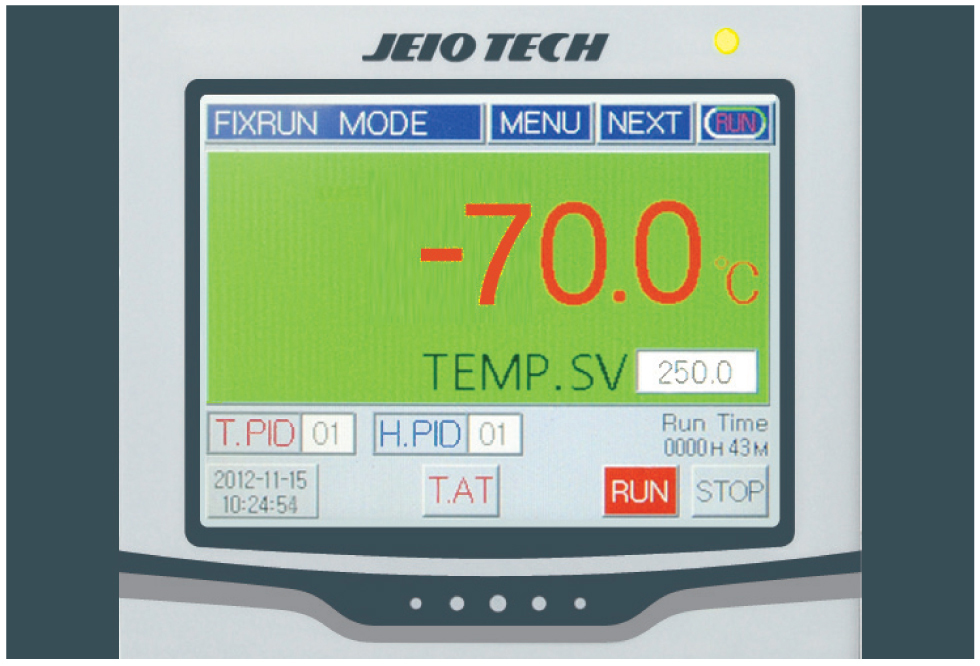

Color LCD controller

Automatic start

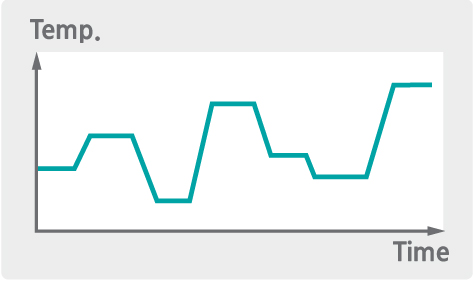

Program control

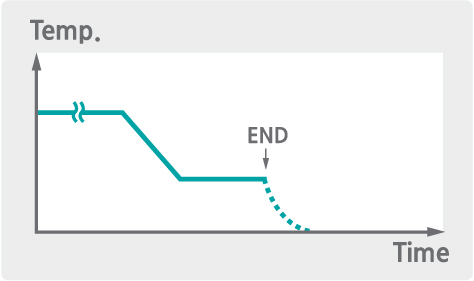

End of program

Function setup

Operating status

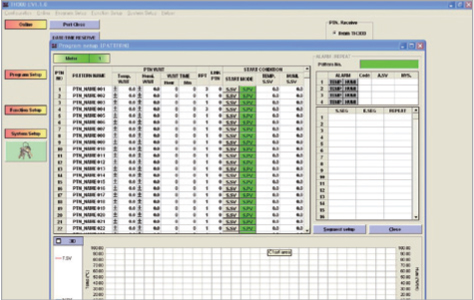

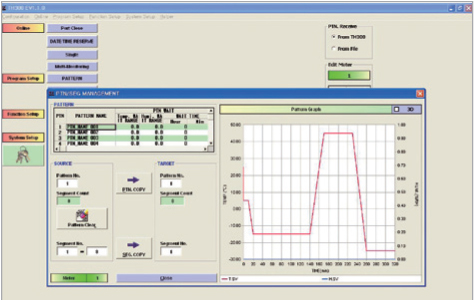

Program setup

Graph display

Performance

- Suitable for specific use such as heat treatment and drying process.

- Microprocessor PID control / Temperature calibration / Automatic tuning.

- Air-tight door closure with double sealed packing.

- Heat-resistant silicone double packing completely blocks high heat leakage from the inner chamber.

- Two-point door latch also enhances tightness to door closure. - Energy efficiency is achieved thanks to optimization of the insulation system.

- Even if the unit is operating at max. temperature, the surface of the unit doesn’t allow high temperatures of over 51℃. (DIN EN 563) - Reliable design and production of door is guaranteed.

- Evaluates the results after opening the door by 90 degrees and applying 50kg load to the point of 30cm from hinges.

Safety

- User selectable operation mode after power interruption

- ether Automatic run or Manual run. - Over-temperature protection.

- Over-current and current leakage protection.

(ELCB, earth leakage circuit breaker) - Independent safety fuse.

- Important parts such as controller and heaters are highly secured from short circuit. Especially each heater has an individual fuse to completely break a short circuit. - Reversed-phase protection.

- Electrical connection error indicator helps user to rapidly fix the connection. - Over-current protection of motor. - Automatic shut-off in situations where there is over-current to the motor.

- Open door warning.

- Heater and fan stop when the door is the open state. - Electric wiring panel access warning.

- Automatic stop if the cover of electric wiring panel is opened. - Built in door lock with a key

Convenience

- Corrosion resistance stainless steel inner chamber.

- Space efficient and easy loading chamber design.

- Included two shelves for loading of large amounts of samples.

- Heavy load shelving, rated for 40kg are also available. (optional) - User friendly LCD controller.

- Colorful interactive touch type LCD controller.

- Set point temperature and present temperature are clearly shown together on display.

- Sufficient programmable control support.

- Operating progress can be shown in graph mode for better data understanding.

- Automatic start/stop can be programmed for unattended operations.

- Display indicates abnormal temperature changes or power failures.

- Three different language support. (English / Chinese / Korean)

- Temperature and other operating parameters can be recorded using a six channel digital recorder. (optional) - Computer interface.

- RS-485 communication port(optional) enables connection up to maximum 32 units. Simultaneous monitoring and operating of multiple units is an available feature.

- Program patterns are simple to set with the use of our software.

- Easy to check status of real-time operations. Graph data supports easy understanding.

- Storage and documentation of programs.

- Data with saving capabilities in excel and text format.

- Storage of program information, backup of value settings, recovery, and temperature values.

- RS-232 communication port as standard offer

| Description | No |

|---|---|

| Programmable pattern capacity | 100 |

| Pattern repeat time | 999 |

| Part repeat time | 255 |

| Max. segments per a pattern | 100 |

| Available max. segments* | 2000 |

| Programmable process time per a segment | 0 to 99 hr. 59 min. |

* Even though the max. segments per pattern are 100, the total available segments are up to 6000 not 10000, therefore arrangement of the number of segment and patterns will need to be done properly.

| Model | KMV-012 | KMV-025 | KMV-040 | KMV-070 | KMV-100 | |

|---|---|---|---|---|---|---|

|

Temperature data |

||||||

|

Range (℃ / ℉) |

-35 to 180 / -31 to 356 |

|||||

|

Fluctuation (±℃ / ℉)1),2) |

at -40℃ |

0.5 / 0.9 |

0.5 / 0.9 |

0.3 / 0.54 |

0.2 / 0.36 |

0.3 / 0.54 |

|

at -25℃ |

0.3 / 0.54 |

0.3 / 0.54 |

0.3 / 0.54 |

0.2 / 0.36 |

0.2 / 0.36 |

|

|

at -10℃ |

0.3 / 0.54 |

0.3 / 0.54 |

0.2 / 0.36 |

0.3 / 0.54 |

0.3 / 0.54 |

|

|

at 25℃ |

0.2 / 0.36 |

0.2 / 0.36 |

0.5 / 0.9 |

0.4 / 0.72 |

0.2 / 0.36 |

|

|

at 70℃ |

0.3 / 0.54 |

0.3 / 0.54 |

0.4 / 0.72 |

0.3 / 0.54 |

0.2 / 0.36 |

|

|

at 100℃ |

0.3 / 0.54 |

0.3 / 0.54 |

0.3 / 0.54 |

0.3 / 0.54 |

0.3 / 0.54 |

|

|

at 150℃ |

0.2 / 0.36 |

0.2 / 0.36 |

0.3 / 0.54 |

0.2 / 0.36 |

0.2 / 0.36 |

|

|

at 180℃ |

0.4 / 0.72 |

0.4 / 0.72 |

0.3 / 0.54 |

0.3 / 0.54 |

0.2 / 0.36 |

|

|

Gradient (±℃ / ℉)1) |

at -40℃ |

0.5 / 0.9 |

0.5 / 0.9 |

1.2 / 2.16 |

0.6 / 1.08 |

0.3 / 0.54 |

|

at -25℃ |

0.6 / 1.08 |

0.6 / 1.08 |

1.2 / 2.16 |

0.7 / 1.26 |

0.4 / 0.72 |

|

|

at -10℃ |

0.7 / 1.26 |

0.7 / 1.26 |

1.2 / 2.16 |

0.8 / 1.44 |

0.4 / 0.72 |

|

|

at 25℃ |

0.7 / 1.26 |

0.7 / 1.26 |

1.1 / 1.98 |

0.8 / 1.44 |

0.5 / 0.9 |

|

|

at 70℃ |

0.8 / 1.44 |

0.8 / 1.44 |

1.7 / 3.06 |

0.9 / 1.62 |

0.7 / 1.26 |

|

|

at 100℃ |

1 / 1.8 |

1 / 1.8 |

1.9 / 3.42 |

1.1 / 1.98 |

0.8 / 1.44 |

|

|

at 150℃ |

1 / 1.8 |

1 / 1.8 |

2.3 / 4.14 |

0.5 / 0.9 |

0.7 / 1.26 |

|

|

at 180℃ |

1.4 / 2.52 |

1.4 / 2.52 |

2.3 / 4.14 |

0.8 / 1.44 |

0.8 / 1.44 |

|

|

Heating time (min)2) |

from -40℃ to 25℃ |

23 |

23 |

23 |

20 |

23 |

|

from -25℃ to 25℃ |

20 |

20 |

19 |

20 |

18 |

|

|

from -10℃ to 25℃ |

14 |

14 |

17 |

15 |

14 |

|

|

from 25℃ to 70℃ |

17 |

17 |

21 |

19 |

21 |

|

|

from 25℃ to 100℃ |

31 |

31 |

29 |

44 |

44 |

|

|

from 25℃ to 150℃ |

61 |

61 |

48 |

82 |

90 |

|

|

from 25℃ to 180℃ |

65 |

65 |

55 |

100 |

76 |

|

|

from -40℃ to 180℃ |

92 |

92 |

79 |

102 |

203 |

|

|

from -25℃ to 120℃ |

68 |

68 |

66 |

67 |

99 |

|

|

from -40℃ to 5℃ |

15 |

15 |

13 |

10 |

19 |

|

|

from 5℃ to 125℃ |

53 |

53 |

54 |

80 |

171 |

|

|

from 125℃ to 180℃ |

24 |

24 |

12 |

12 |

13 |

|

|

Cooling time (min)2) |

from 25℃ to -40℃ |

41 |

41 |

37 |

38 |

44 |

|

from 25℃ to -25℃ |

20 |

20 |

20 |

17 |

20 |

|

|

from 25℃ to -10℃ |

13 |

13 |

15 |

10 |

15 |

|

|

from 70℃ to 25℃ |

16 |

16 |

16 |

13 |

15 |

|

|

from 100℃ to 25℃ |

25 |

25 |

25 |

18 |

27 |

|

|

from 150℃ to 25℃ |

81 |

81 |

110 |

103 |

290 |

|

|

from 180℃ to 25℃ |

152 |

152 |

173 |

177 |

310 |

|

|

from 180℃ to -40℃ |

180 |

180 |

221 |

212 |

361 |

|

|

from 120℃ to -25℃ |

43 |

43 |

46 |

48 |

48 |

|

|

from 180℃ to 125℃ |

113 |

113 |

150 |

153 |

292 |

|

|

from 125℃ to 5℃ |

33 |

33 |

36 |

27 |

31 |

|

|

from 5℃ to -40℃ |

34 |

34 |

35 |

32 |

38 |

|

|

Recovery time after door was opened for 30sec (min)2) |

at -40℃ |

8 |

8 |

6.5 |

7 |

6 |

|

at -25℃ |

3.5 |

3.5 |

7.5 |

6 |

7 |

|

|

at -10℃ |

2.5 |

2.5 |

6.5 |

6.5 |

6.5 |

|

|

at 25℃ |

4 |

4 |

5.5 |

4.5 |

5 |

|

|

at 70℃ |

4 |

4 |

5.5 |

5 |

8 |

|

|

at 100℃ |

4 |

4 |

6.5 |

6 |

6 |

|

|

at 150℃ |

4 |

4 |

4.5 |

4.3 |

3.5 |

|

|

at 180℃ |

11.5 |

11.5 |

6 |

5 |

4 |

|

|

Chamber volume (L / cu ft) |

125 / 4.41 |

253 / 8.93 |

420 / 14.83 |

720 / 25.43 |

1000 / 35.31 |

|

|

Quantity of shelves (standard / max) |

2 / 6 |

2 / 9 |

2 / 11 |

2 / 15 |

2 / 16 |

|

|

Distance of between shelves (mm / inch) |

30 / 1.2 |

|||||

|

Max. load per shelf (kg / lbs) |

15 / 33.1 |

20 / 44.1 |

30 / 66.1 |

40 / 88.2 |

45 / 99.2 |

|

|

Permitted total load (kg / lbs) |

50 / 110.2 |

70 / 154.3 |

90 / 198.4 |

120 / 264.6 |

150 / 330.7 |

|

|

Dimension (W×D×H) |

Interior (mm / inch) |

500×500×500/ 19.7×19.7×19.7 |

600×650×650/ 23.6×25.6×25.6 |

750×700×800/ 29.5×27.6×31.5 |

900×800×1000/ 35.4×31.5×39.4 |

1000×910×1100/ 39.4×35.8×43.3 |

|

Exterior (mm / inch) |

1070×775×1385/ 42.1×30.5×54.5 |

1170×925×1585/ 46.1×36.4×62.4 |

1370×975×1780/ 53.9×38.4×70.1 |

1495×1625×1650/ 58.9×64×65 |

1595×1725×1800/ 62.8×67.9×70.9 |

|

|

Net weight (kg / lbs) |

170 / 374.8 |

260 / 573.2 |

320 / 705.5 |

390 / 859.8 |

440 / 970 |

|

|

Interface port |

Basically RS-232C [RS-485(maximum 32 units control)-optional] |

|||||

|

Electrical data & Ordering information |

||||||

| Electrical requirements (230V, 60Hz, 1P, A) | 19.2 | 26 | ||||

| Cat. No. | AAHK9011K | AAHK9021K | - | - | - | |

| Electrical requirements (230V, 50Hz, 1P, A) | 19.2 | 26 | ||||

| Cat. No. | AAHK9015K | AAHK9025K | - | - | - | |

| Electrical requirements (380V, 50Hz, 3P, A) | 12.5 | 18 | 19.4 | |||

| Cat. No. | - | - | AAHK9030K | AAHK9040K | AAHK9050K | |

1) According to IEC 60068-3-5

2) According to DIN 12880

※ Above specification value is recorded by 230V/60Hz, 380V/50Hz.

※ Above specifications can be changed without prior notice.

-

Digital recorder

-

Perforated shelf

-

Warning signal lamp

for Floor Standing Chambers

| Cat. No. | Description | Models |

|---|---|---|

| KMV | ||

| AAA8T505 |

Recorder (digital, 6 channels) |

|

| AAA8T540 |

Interface converter (RS - 485 → 232) included a cable (5m / 16.4ft) |

|

| AAA80550 |

Warning signal lamp |

|

| 00LTV0000070 |

Wire shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-012 (462x470mm / 18.2x18.5”) |

|

| 00LTV0000053 |

Wire shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-025 (562x620mm / 22.1x22.4”) |

|

| 00LTV0000029 |

Wire shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-040 (712x670mm / (28.0x26.4”) |

|

| 00LTV0000030 |

Wire shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-070 (862x770mm / 33.9x30.3”) |

|

| 00LTV0000057 |

Wire shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-100 (962x880 / 37.9x34.6”) |

|

| AAAK1501 |

Perforated shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-012 (462x470mm / 18.2x18.5”) (max. load 40kg) |

|

| AAAK1502 |

Perforated shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-025(562x620mm / 22.1x22.4”) (max. load 40kg) |

|

| AAAK1503 |

Perforated shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-040 (712x670mm / (28.0x26.4”) (max. load 40kg) |

|

| AAAK1504 |

Perforated shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-070 (862x770mm / 33.9x30.3”) (max. load 40kg) |

|

| AAAK1505 |

Perforated shelf for LBV/LTV/KBD/KMV/JMV/PBV/PMV-100 (962x880 / 37.9x34.6”) (max. load 40kg) |

|

Related Products

Inquiry Form