PRODUCTS

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubator, Air-jacket (Standard, IB4-AS)

- Incubator, Air-jacket (Advanced, IB4-AV)

- Incubator, Forced Convection (Standard, IB4-S)

- Incubator, Forced Convection (Advanced, IB4-V)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Natural Convection Oven (Standard, ON4-S)

- Natural Convection Oven (Advanced, ON4-V)

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Vertical Electrophoresis System

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Ovens

- HOME

- > PRODUCTS

- > Ovens

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubator, Air-jacket (Standard, IB4-AS)

- Incubator, Air-jacket (Advanced, IB4-AV)

- Incubator, Forced Convection (Standard, IB4-S)

- Incubator, Forced Convection (Advanced, IB4-V)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Natural Convection Oven (Standard, ON4-S)

- Natural Convection Oven (Advanced, ON4-V)

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Vertical Electrophoresis System

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Forced Convection Ovens (Program, OF3-P)

Specially designed for large volume and fast drying application. (max. 760L and 300℃)

Offering rapid heating performance as well as uniform temperature distribution, these heavy-duty ovens are ideal for obtaining quick test results.

Model Name : OF3-30P/45P/75P, 30HP/45HP/75HP

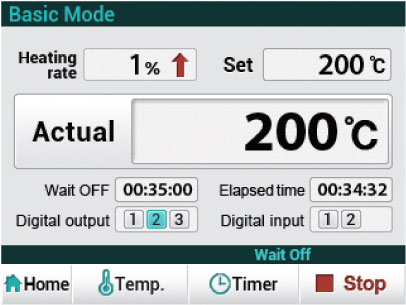

Programmable model (OF3-P/PH)

for intelligent program control

Color touch LCD display

- 10 programs available for temperature ramp up and dwell control.

- 10 steps per a program and 99 hours 59 minutes per a step.

- Stored programs are easily linkable.

- Programs can be repeated up to 99 cycles.

- Pre-heating and heating time are settable before program starts.

Performance

- Rapid heating performance up to maximum 300°C

- Microprocessor PID control.

- Three point temperature calibration / Automatic tuning.

- Forced air convection generated by two noiseless and powerful sirocco fans ensures optimal air circulation, temperature uniformity, and short heat-up time.

- Adjustable dual slide vents for inner vapor circulation.

- Energy efficiency is achieved thanks to optimization of the insulation system.

- Even if the unit is operating at max. temperature, the surface of the unit doesn’t allow high temperatures.

Convenience

- Optimum model selection is available according to two different types of control panel.

- Intuitive touch screen LCD controller with easy icons and logical menus. (for OF3P/HP) - Dual wait on/off timer modes. (1 min. to 99 hr. 59 min.)

- Convenient presetting function for 3 most commonly used temperature settings.

- Rounded inner chamber corners for easy cleaning and optimal airflow.

- Corrosion-resistant incoloy sheath heating element and stainless steel interior.

- Threefold tempered-glass window provides clear inside view of the chamber. (optional)

- USB port and RS-232 port for external control and data collection.

- Casters for easy mobility during installation or relocation.

Safety

- Keypad lock function prevents accidental changes during operation.

- Automatic run after power interruption.

- Over-temperature and over-current protection.

- Audible and visible open door alarms.

| Programmable Model | OF3-30P | OF3-45P | OF3-75P | OF3-30HP | OF3-45HP | OF3-75HP | ||

|---|---|---|---|---|---|---|---|---|

|

Chamber volume (L / cu ft) |

314 / 11.1 |

450 / 15.9 |

760 / 26.8 |

314 / 11.1 |

450 / 15.9 |

760 / 26.8 | ||

|

Temperaure |

Range (℃ / ℉) |

Amb. +15 to 200 / Amb.+27 to 392 |

Amb. +15 to 300 / Amb.+27 to 572 | |||||

|

Fluctuation 1) at 100℃ (±℃ / ℉) |

0.2 / 0.36 |

0.2 / 0.36 | ||||||

|

Variation 1) at 100℃ (±℃ / ℉) |

2.0 / 3.6 |

2.2 / 4.0 |

2.5 / 4.5 |

2.0 / 3.6 |

2.2 / 4.0 |

2.5 / 4.5 | ||

|

Dimension (W×D×H) |

Interior (mm / inch) |

645×750×650 / 25.4×29.5×25.6 |

645×750×930 / 25.4×29.5×36.6 |

745×850×1200 / 29.3×33.5×47.2 |

645×750×650 / 25.4×29.5×25.6 |

645×750×930 / 25.4×29.5×36.6 |

745×850×1200 / 29.3×33.5×47.2 | |

|

Exterior (mm / inch) |

850x1100x1235 / 33.5x43.3x48.6 |

850x1100x1525 / 33.5x43.3x60 |

950x1200x1785 / 37.4x47.2x70.3 |

850x1100x1235 / 33.5x43.3x48.6 |

850x1100x1525 / 33.5x43.3x60 |

950x1200x1785 / 37.4x47.2x70.3 | ||

|

Net weight (Kg / lbs) |

200 / 440.9 |

240 / 529.1 |

300 / 661.4 |

200 / 440.9 |

240 / 529.1 |

300 / 661.4 | ||

|

Shelves |

No. of wire shelf (standard / max.) |

2 / 5 |

3 / 8 |

3 / 11 |

2 / 5 |

3 / 8 |

3 / 11 | |

|

Max. load per shelf (kg / Ibs) |

25 / 55.1 |

25 / 55.1 | ||||||

| Electrical requirements (230V, 50/60Hz, A) | 1P, 13.2 | |||||||

| Cat No. | Solid door | AAH18615K | - | - | - | - | - | |

| Window door | AAH18715K | - | - | - | - | - | ||

| Electrical requirements (380V, 50Hz, A) | 3P, 6.7 | 3P, 9.0 | 3P, 6.7 | 3P, 9.0 | 3P, 10.8 | |||

| Cat No. | Solid door | - | AAH186214K | AAH186314K | AAH196114K | AAH196214K | AAH196314K | |

| Window door | - | AAH187214K | AAH187314K | AAH197114K | AAH197214K | AAH197314K | ||

1) Technical data according to DIN 12880.

※ CE for 380V, 50/60hz.

for Forced / Natural convection ovens

-

Wire shelves

-

Perforated shelves

-

Tempered viewing windows

-

Fan speed adjuster

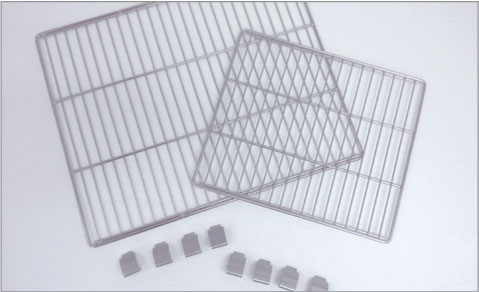

Wire shelves

Stainless steel and electro-polished shelf system is removed easily without using tools for easy cleaning.

| Cat. No. | Description | Suitable for | ||||

|---|---|---|---|---|---|---|

| Included | Maximum | W×L (mm / inch) | ||||

| 00RTD0001196 | 2 | 5 | 708×608 / 27.9×23.9 | OF3-30/P/H/HP | ||

| 3 | 8 | OF3-45/P/H/HP | ||||

| 00RTD0001197 | 3 | 11 | OF3-75/P/H/HP | |||

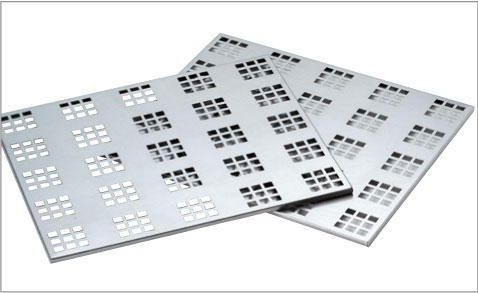

Perforated shelves

Stainless steel shelf system is removed easily without using tools for easy cleaning.

| Cat. No. | Description | Suitable for | |

|---|---|---|---|

| Maximum | W×L (mm / inch) | ||

| AAA18501 |

5 | 708×608 / 27.9×23.9 | OF3-30/P/H/HP |

| 8 | OF3-45/P/H/HP | ||

| AAA18502 | 11 | OF3-75/P/H/HP | |

Recorders

Easy recognizable digital recorders for efficient temperature indicating.

| Cat. No. | Description | Suitable for |

|---|---|---|

| AAA8T500 | Recorder (6 point) |

OF3-30/P/H/HP

OF3-45/P/H/HP

OF3-75/P/H/HP |

| AAAE1503 | Recorder (thermal line type) |

Gateway

Establish Jeio Tech Network by Gateway. No computer use is required at all. Remote monitoring of operating status through a mobile phone is simply available when you place a Gateway in your laboratory. Maximum 4 units can be connected to Gateway by RS-232 cable.

| Cat. No. | Description | |

|---|---|---|

| AAHQ1011K | Gateway (2.4GHz, 100~240V, 50/60Hz) | |