PRODUCTS

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubators (General, Air-jacket)

- Incubators (Film Heater, Economy)

- Incubators (Multi type Forced Convention)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Natural Convection Ovens (General, ON)

- Natural Convection Ovens (Economy)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Ovens

- HOME

- > PRODUCTS

- > Ovens

Ovens

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubators (General, Air-jacket)

- Incubators (Film Heater, Economy)

- Incubators (Multi type Forced Convention)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Natural Convection Ovens (General, ON)

- Natural Convection Ovens (Economy)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

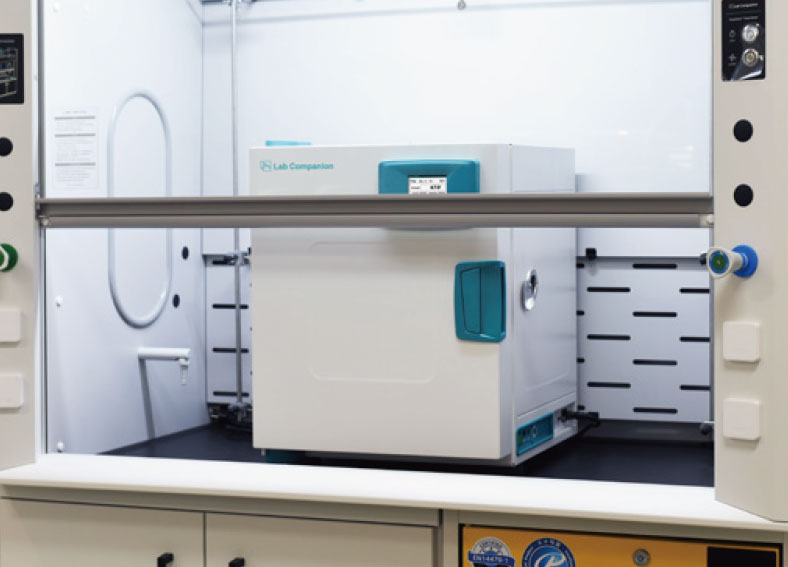

Forced Convection Ovens (Standard, OF4-S)

Affordable oven that is faithful to the basic functions.

Model Name : OF4-03S(W) / 05S(W) / 10S(W) / 15S(W)

Standard type that provides the device information intuitively (OF4-S)

- 3.5-Inch touch controller that enables intuitive control of the device.

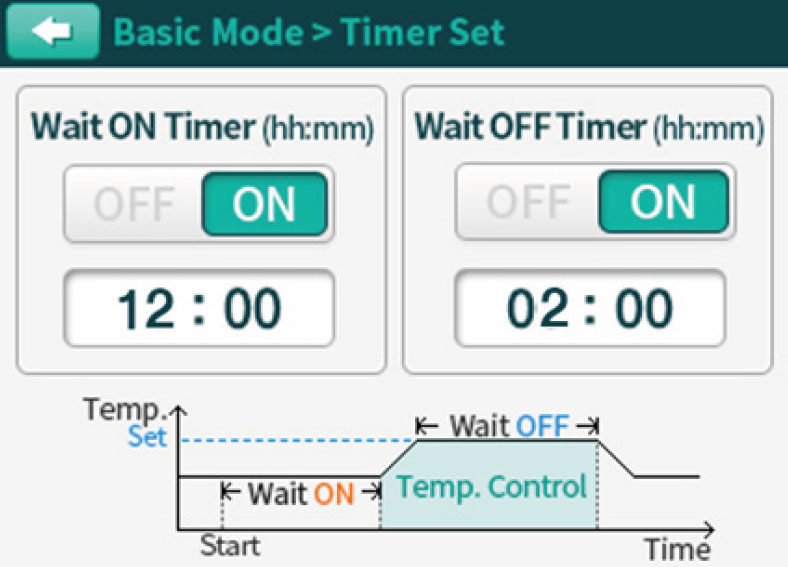

- Wait on/Wait off timer setting allowing efficient test schedule management.

3.5-Inch touch controller

Wait on & Wait off Timer

Reliable temperature control performance based on stable control mechanisms

- Wide temperature range of up to 250℃.

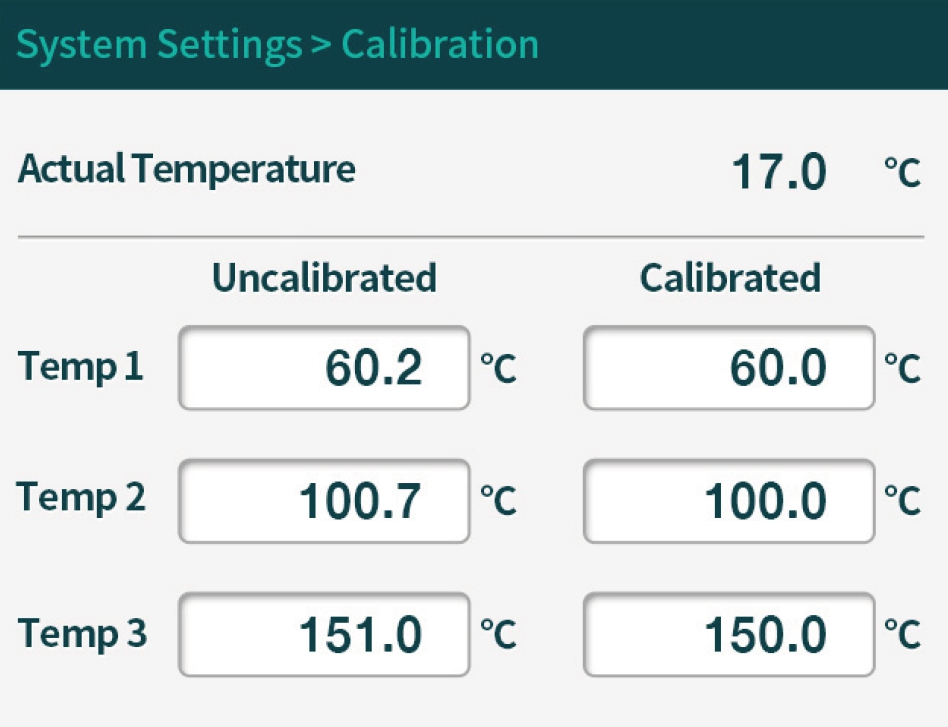

- Three-point temperature calibration that ensures hightemperature accuracy over a wide temperature range.

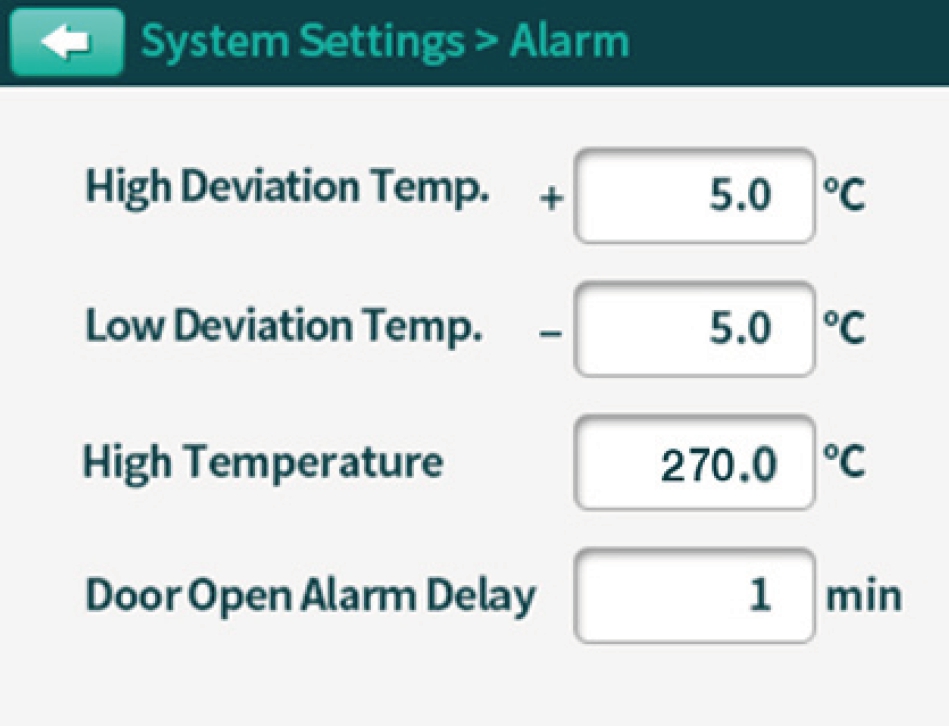

- Available to set the upper and lower temperature limit, alarm activated to quick response when occurring the deviation.

- Excellent temperature distribution through the formation of optimal airflow for uniform heat transfer.

(±1.9℃ or below at 100℃)

Three-point temperature calibration that ensures precise temperature control

Temperature deviation setting

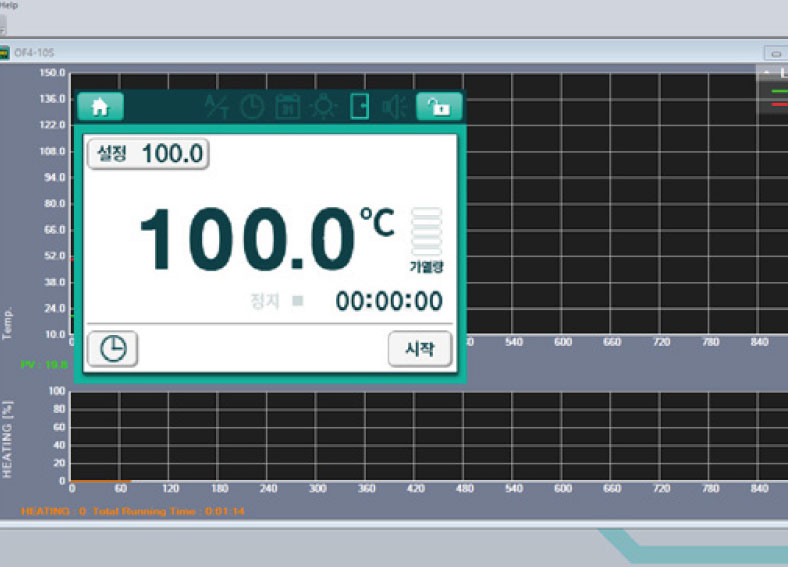

Convenient checking for the test progress and data

- RS-232/USB port and compatible software provided to enable easy device control and data management using PC. (option)

- Monitor and control via mobile app anytime, anywhere with LC Connected. (mobile monitoring system) (option)

- BMS communication port that helps monitor the device temperature on the building management system. (option)

Control via connecting the PC

Real-time monitoring and control via mobile (option)

Various safety features for improved user safety

- The upper vent hole releases effectively fume inside the oven when using local ventilation equipment. (OF4-03)

- Device surface not overheating even in operation at the highest temperature. (70℃ or below, at 250℃)

- Top-rated overheating protection system. (registration KR 10-0397583)

- Over temperature limit function.

- Equivalent to IEC protection Class II.

Fumes inside the chamber effectively removed

Safe surface of the device even in operation at the highest temperature

Structural and functional features for improved user convenience

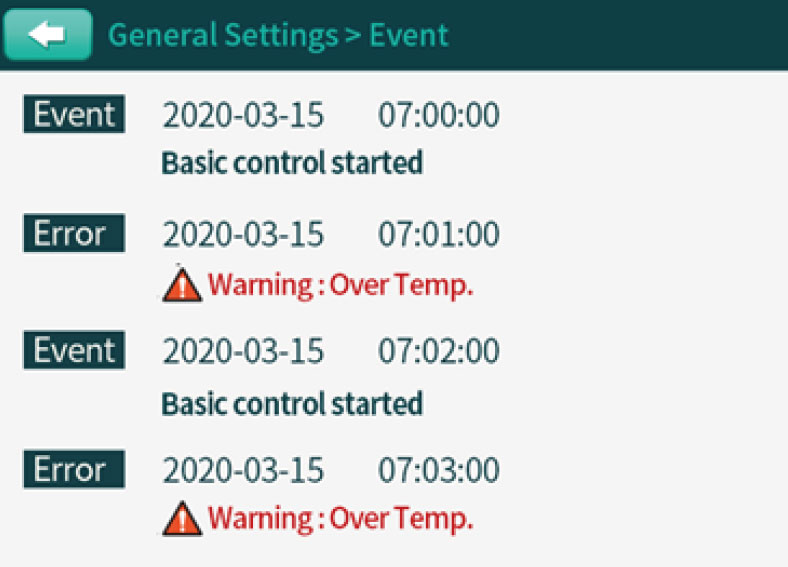

- Recording the 12 most recent events, such as start/stop of operation, the operating time, and error occurrence.

- Stacking Kit (option) ensuring the safe fitting of one unit to another, thus doubling the amount of work done in a given area for improved space efficiency.

- Hands-free™ door system to allow users to easily open the door while carrying samples with both hands. (±1.9℃ or below at 100℃)

Up to 12 latest events automatically recorded

Two-unit stacking for improved space efficiency (option)

Spec

| Model | Solid door (without window) | OF4-03S | OF4-05S | OF4-10S | OF4-15S | |||

|---|---|---|---|---|---|---|---|---|

| Window door | OF4-03SW | OF4-05SW | OF4-10SW | OF4-15SW | ||||

| Chamber volume (L/cu ft) | 26/0.92 | 61/2.15 | 112/3.96 | 147/5.19 | ||||

| Temperature 1) | Range (℃/℉) | Amb. + 10~250 / Amb. + 18 ~ 482 | ||||||

| Fluctuation at 100℃ (±℃/±℉) | 0.3/0.54 | 0.3/0.54 | 0.3/0.54 | 0.3/0.54 | ||||

| Variation at 100℃ (±℃/±℉) | 1.4/2.52 | 1.9/3.42 | 1.7/3.06 | 1.5/2.70 | ||||

| Heating time to 100℃ (min) | 8 | 10 | 14 | 15 | ||||

| Recovery time at 100℃ (min) | 4 | 4 | 4 | 4 | ||||

| Control Panel | 3.5inch TFT Color LCD | |||||||

| Communication interface | USB, RS-232 (Option) | |||||||

| Function | Recently event record | 12ea | ||||||

| Dimensions | Interior (W x D x H, mm/inch) | 300 x 210 x 400 / 11.80 x 8.27 x 15.75 |

380 x 330 x 480 / 14.97 x 13.0 0x 18.90 |

485 x 350 x 655 / 19.09 x 13.78 x 25.79 |

550 x 376 x 710 / 21.65 x 14.80 x 27.95 |

|||

| Exterior (W x D x H, mm/inch) | 478 x 527 x 604 / 18.82 X 20.75 X 23.78 |

558 x 648 x 684 / 21.97 X 25.51 X 26.93 |

663 x 677 x 859 / 26.1 X 26.65 X 33.82 |

728 x 704 x 914 / 28.66 X 27.72 X 35.98 |

||||

| Net weight (kg/lbs) | 33/72.8 | 53/116.8 | 63/138.9 | 73/160.9 | ||||

| Shelves | Quantity of shelves (Standard/max.) |

2/4 | 2/5 | 2/8 | 2/9 | |||

| Max. Load per shelf (kg/lbs) | 30/66.1 | |||||||

| Number of Air change per hour at 100 ℃ 2) | 123 | 22 | 18 | 11 | ||||

| Electrical requirements (230V, 50/60Hz, A) | 6.4 | |||||||

| Cat. No. | Solid door (without window) | AAH14115K | AAH14125K | AAH14135K | AAH14145K | |||

| Window door | AAH14215K | AAH14225K | AAH14235K | AAH14245K | ||||

| Electrical requirements (120V, 60Hz, A) | 12.3 | |||||||

| Cat. No. | Solid door (without window) | AAH14116U | AAH14126U | AAH14136U | AAH14146U | |||

| Window door | AAH14216U | AAH14226U | AAH14236U | AAH14246U | ||||

1) This data was measured when the fan speed was set to Step 5. If the fan speed is set to Step 1 or Step 3, the fluctuation and variation values will increase. (According to DIN 12880, before 2013)

2) This data was measured when the fan speed was set to Step 5. If the fan speed is set to Step 1 or Step 3, the number of air changes may decrease. (According to ASTM D 5374, reapproved 1999)

2) This data was measured when the fan speed was set to Step 5. If the fan speed is set to Step 1 or Step 3, the number of air changes may decrease. (According to ASTM D 5374, reapproved 1999)

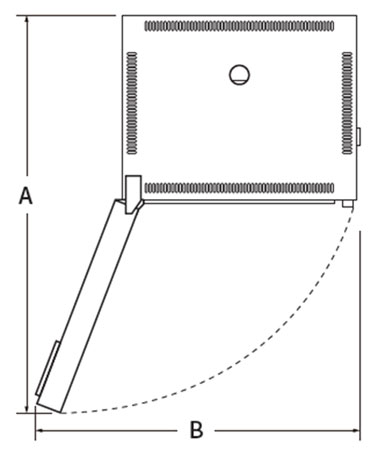

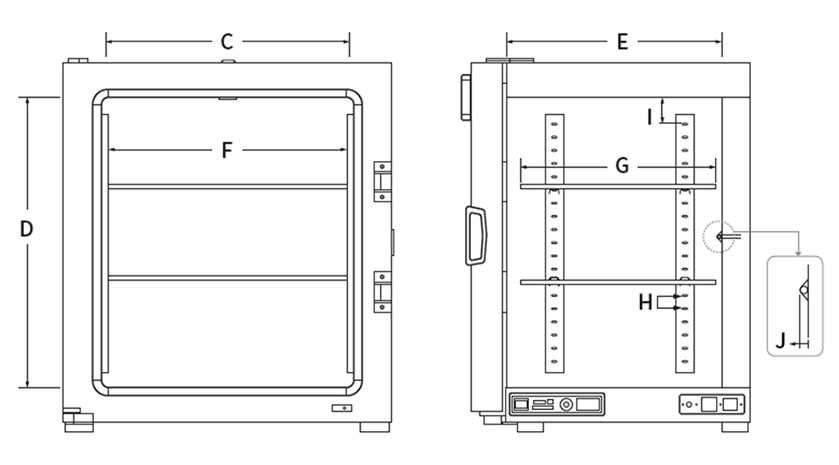

Dimensions

- Exterior

- Interior

(unit: mm / inch)

| Model | OF-03P | OF4-05P | OF4-10P | OF4-15P | |

|---|---|---|---|---|---|

| A: Maximum depth with door opened | 868 / 34.2 | 1060 / 41.7 | 1185 / 46.7 | 1271 / 50.0 | |

| B: Maximum width with door opened | 695 / 27.4 | 809 / 31.9 | 958 / 37.7 | 1050 / 41.3 | |

| C: Interior width | 300 / 11.8 | 380 / 15.0 | 485 / 19.1 | 550 /21.7 | |

| D: Interior height | 400 / 15.7 | 480 / 18.9 | 655 / 25.8 | 710 / 28.0 | |

| E: Interior depth | 210 / 8.3 | 330 / 13.0 | 350 / 13.8 | 376 / 14.8 | |

| F: Shelve width | 266 / 10.5 | 346 / 13.6 | 451 / 17.8 | 516 / 20.3 | |

| G: Shelve depth | 195 / 7.7 | 315 / 12.4 | 335 / 13.2 | 361 / 14.2 | |

| H: Gap between shelf racks | 30 / 1.2 | 30 / 1.2 | 30 / 1.2 | 30 / 1.2 | |

| I: Gap between uppermost shelve and interior ceiling | 80 / 3.1 | 90 / 3.5 | 88 / 3.5 | 85 / 3.3 | |

| J: Space for sensor installation | 3.8 / 0.15 | 3.8 / 0.15 | 3.8 / 0.15 | 3.8 / 0.15 | |

for Forced / Natural convection ovens

Wire shelf (Include 2ea as standard)

- · Stainless Steel

- · Excellent air permeability and uniform temperature distribution.

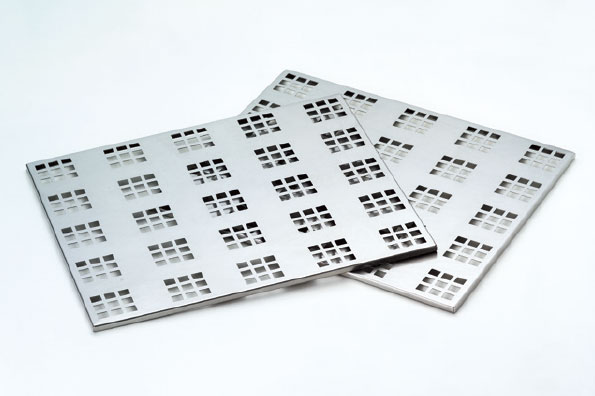

Perforated shelf

- · Stainless Steel

- · Solid structure makes it suitable for high load samples.

Double-stacked bracket

- · Use for stacking 2 units.

- · Improve space efficiency with the sturdy stacking.

※ When install the double-stacked bracket, the temperature control range of the upper oven is decrease

(Amb.+30 ~ 250℃ / Amb.+54 ~ 482℉)

BMS Port

- · Real-time monitoring at a central monitoring facility.

- · Easier to ensure safety, especially in labs where multiple units are operated.

LC GreenBox(Mobile Monitoring System)

- · Remote monitoring and control via mobile application.

- · One LC GreenBox can connect up to 4 devices.

- · Connect using RS-232 port on the communication port.

Communication Port

- · Control PC connection and data by dedicated software.

- · Included as default in OF4-P/V and ON4-V and optional for OF4-S and ON4-S

| Model | OF4-03 | OF4-05 | OF4-10 | OF4-15 |

|---|---|---|---|---|

| Wire shelf | 00FDA0009739 | 00FDA0009738 | 00FDA0009737 | 00FDA0009736 |

| Perforated shelf | AAA125341 | AAA125342 | AAA125343 | AAA125344 |

| Double-stacked bracket | AAA125531 | AAA125531 | AAA125532 | AAA125532 |

| Model | OF4-P/V | OF4-S |

|---|---|---|

| BMS port | AAA125534 | AAA125534 |

| LC GreenBox | AAHQ1011K | AAHQ1011K |

| Communication port | standard | AAA125523 |

;

Jeio Tech Forced Convection Oven (OF4) series introduction

Related Products

Inquiry Form