How to Check the Condition of Filtered Products.

Greetings! At JEIO TECH Lab Companion.

JEIO TECH has a variety of equipment with built-in filters such as a Ductless Fume Hood (DLH), Mobile Fume Extractor (EFS), Filtering Storage Cabinet (FSC), and Filtering Storage Refrigerator (FSR) because laboratories reap a wide array of safety hazards from chemical fumes and dust to toxic compounds.

However, when to replace those filters is often an overlooked question in several laboratories. The specific method for checking the condition of a filter depends on the type of products and the nature of the filtration process used such as filter material, filtration area, structural design, initial resistance, etc.

Some equipment such as the Filtering Storage Cabinet (FSC), and the Filtering Storage Refrigerator (FSR) have a filter maintenance notification function (Set-up the recommended 6 months) of a 1-24 month cycle which makes it easy to manage the filter according to the usage environment. Even before the recommended filter inspection cycle, you must check and replace the filter if any unusual odors that could indicate contamination or spoilage are detected.

Then, how do we check the conditions of a filter?

In order to check the condition, you need the appropriate device, a detector tube, and its pump (KITAGAWA, AP-20).

Detector tubes are used to measure the concentration of a specific gas or vapor. They are often used in industrial settings to monitor for potential hazards, such as toxic gases. A pump can be used to draw air through the detector tube, which will then react with the targeted gas or vapor and produce a color change in the tube.

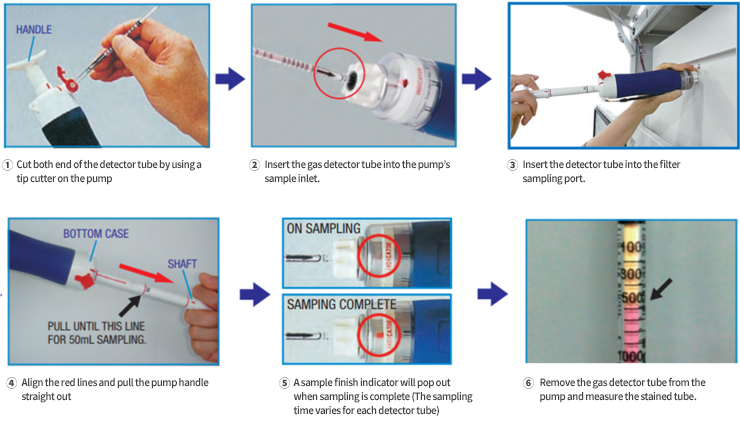

Here are the steps for filtering checks using a detector tube and pump.

You may check the stained detector tube to ensure that it meets the TWA standards prescribed by the Occupational Safety and Health Act. If the concentration of the detector tube is above the exposure standard, please contact the JEIO TECH sales office to replace the filter.

The followings are the Time-Weighted Average (multiplying the measurement value of harmful factors by the occurrence time and dividing it by 8 hours, based on working 8 hours a day) standard for concentrations of major chemicals.

|

Toxic dust

|

TWA (ppm)

|

Toxic dust

|

TWA (ppm)

|

| Benzene |

1 |

Chloroform |

10 |

| Toluene |

50 |

Formaldehye |

0.5 |

| Aceton |

500 |

Ammonia |

25 |

It is important to know the condition of your laboratory equipment. As filters play a crucial role in providing you with a safe environment, it is essential to check the filters at the right time to ensure that you get a safe laboratory.

Proper chemical waste disposal practices are essential for the safe research environments.

JEIO TECH is committed to improving such safety through its Lab Companion products.

To ensure this, we continually listen to and reflect on customer feedback.

Thank you for your ongoing support.

|