|

Hello.

We are the JEIO TECH Lab Companion

Among the various equipment in the laboratory, the most common product is Chamber-type which is based on controlling the temperature. There are various kinds of chambers depending on the purpose of use - such as General ovens used for drying glassware or solvent, Vacuum ovens to dry under the vacuum state, Incubators for tissue cultures, and Temperature and Humidity chambers available to control the humidity as well used for the reliability test. Apart from these, the chamber can be subdivided into the temperature control range, and volume as well, but basically, all this equipment has a common characteristic that can create the desired environmental temperature.

You might be wondering how the chamber can set up the accurate temperature we desired.

Let’s take a closer look at how the JEIO TECH chamber considers when designing a chamber with accurate temperature control.

Temperature Consideration

When using chambers involving important temperature settings such as ovens or incubators, various terms and considerations can be encountered. You may see specifications including temperature fluctuation, temperature variation, and overshooting of temperature on each product as well as the recovery time. These might appear to measure essentially the same thing, but there are subtle yet important differences.

I. Variation

Temperature Variation refers to the uniformity in temperature between different points, in this case within the internal environment of the chamber where the samples are held. Temperature measurement at one point may give a slightly different reading to one at another point.

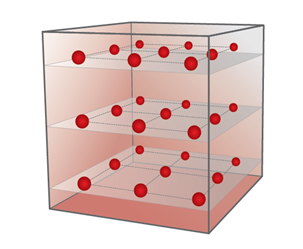

Each term refers to the instrument’s ability to measure or maintain temperature with a certain precision against a particular reference point by a Temperature Sensor (as Figure 1). According to DIN 12880, the temperature should be measured in three horizontal levels which are composed of 9 measuring points in each level, equally distributed across the inner chamber (see Figure 2). This requirement also applies, if a level is hindered by assemblies in the working chamber.

Figure 1 ㅣ 27 Temp. measurement points in accordance with DIN 12880

Figure 2 ㅣ Temperature Sensor

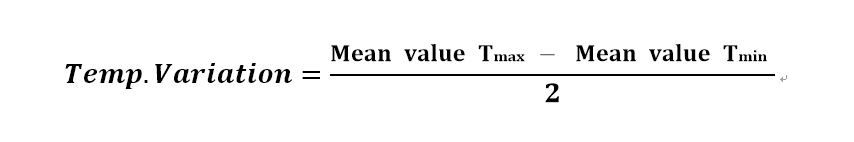

To check the variation value, measurement must be followed based on the above instruction. However, the temperature variation is not the average value of the data measured over a certain period, but the difference between the actual maximum and minimum temperatures (see Figure 3).

Figure 3 ㅣ Temp. curves of three measuring points

II. Fluctuation

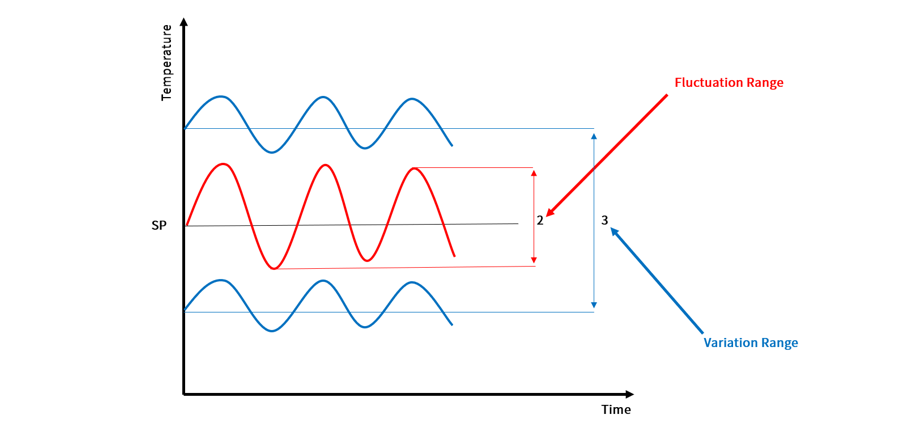

Temperature Fluctuation refers to the stability in temperature which measures the precision of the instrument in maintaining a set-point temperature. It is also expressed as a plus/minus value (see Fluctuation range in Figure 4). For example, the actual chamber temperature with one set-point of “100°C” and a temperature fluctuation of ±0.2°C may vary from 99.8°C to 100.2°C

Figure 4 ㅣ Temp. curves of three measuring points

III. Overshooting

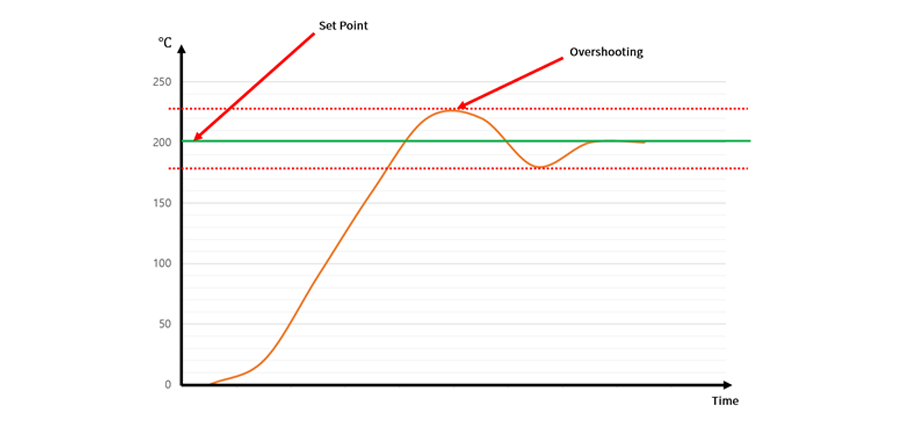

When the chamber heats to a preset temperature, it is normal for the temperatures to overshoot before stabilization. A generally accepted range of temperature overshoots within a specific range. Once it is stable, the chamber should maintain the specified uniformity. For example, the actual temperature will overshoot above the set temperature before cooling back to the setpoint if a chamber temperature is set. Chambers will heat and cool at different rates, so the specified time is standardized in a preheated chamber (see Figure 5)

Figure 5 ㅣ Heating up time graph

VI. Recovery Time (after the door is opened)

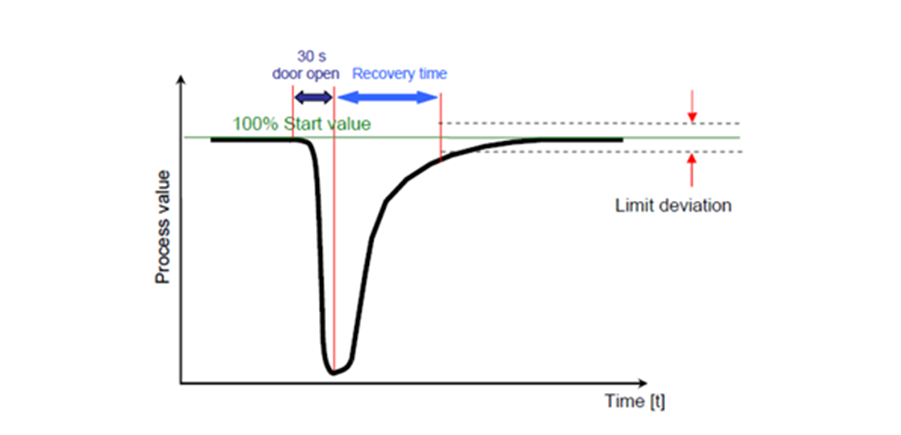

The definition of recovery time according to the new standard of DIN 12880:2007-05 is that when the temperature has stabilized, the door of the oven or incubator is opened for 30 seconds and the time is measured until the actual temperature in the middle of the working space remains permanently within the limit deviation. (see Figure 6)

Figure 6 ㅣ Recovery time graph

For more information about our Oven Series (here)

We hope you may consider precisely when selecting the chambers with appropriate usage.

We will continue to strive to enhance the quality of our products and services

by listening to and reflecting on the feedback of customers through sales, services, validation, etc.

JEIO TECH is creating safer research environments through Lab Companion,

the best partner of researchers and experimenters

We thank you for your support.

|