PRODUCTS

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubators (General, Air-jacket)

- Incubators (Film Heater, Economy)

- Incubators (Multi type Forced Convention)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Natural Convection Ovens (General, ON)

- Natural Convection Ovens (Economy)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Industrial Test Equipment

- HOME

- > PRODUCTS

- > Industrial Test Equipment

- Autoclaves

- Baths & Circulators

- Chiller (Recirculating Cooler)

- Desiccators

- Environmental Chambers

- Temperature & Humidity Chamber Basic type (TH3-E)

- Temperature & Humidity Chamber Tabletop type (TH3-PE)

- Temperature & Humidity Chamber Tabletop type (TH3-ME)

- Temperature & Humidity Chamber Tabletop type (TH3-KE)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Fume Hoods

- Heating & Cooling Block

- Hotplate Stirrers & Stirrer

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate (Digital type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Heating Block (for Round Flask and Vial)

- Incubators

- Incubators (General, Air-jacket)

- Incubators (Film Heater, Economy)

- Incubators (Multi type Forced Convention)

- Low Temperature Incubators (Forced Convection)

- Low Temp. Incubators (Air-jacketed)

- Low Temperature Incubator (Personal)

- Low Temperature Incubator (Multi type, Forced Convention)

- Incubated Shakers (Tabletop)

- Incubated Shakers (Floor)

- Incubated Shaker (Multi-Stackable)

- Incubated Shaker (Stackable)

- Incubator (Mini type, Forced Convention)

- Industrial Test Equipment

- Forced Convection Ovens (Large-General)

- Forced Convection Ovens (Program, OF3-P)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G Type)

- Chiller (Recirculating Coolers) (General)

- Chiller (Recirculating Coolers) (Low Temp. General)

- Chiller (Recirculating Coolers) (High Temp. Precision)

- Temperature & Humidity Chamber (Low Temp. TH-G)

- Temperature & Humidity Chambers Low Temperature (TH-KH)

- Temperature & Humidity Chamber (General TH-TG)

- Pharmaceutical Stability Test Chamber

- Plant Growth Chambers

- Mixers

- Vortex Mixer

- Magnetic Stirrers (Analog)

- Magnetic Stirrers (Digital)

- Magnetic Stirrers (Multi Position)

- Hotplate & Magnetic Stirrers (Analog type)

- Hotplate & Magnetic Stirrers (Digital type)

- Hotplate & Magnetic Stirrers (Multi type)

- Overhead Stirrers (Prestige touch)

- Overhead Stirrers (High Performance)

- Overhead Stirrers (Easy Control)

- Shaker (Compact)

- Microplate Shaker

- Rocking Shaker

- Waving Shaker

- Heating Shaker

- Ovens

- Vacuum Ovens

- Vacuum Ovens, OV4-S

- Forced Convection Ovens (Standard, OF4-S)

- Forced Convection Ovens (Advanced, OF4-V)

- Forced Convection Ovens (Program, OF4-P)

- Forced Convection Ovens (Program, OF3-P)

- Forced Convection Ovens (Large-General)

- Forced Convection Oven (Multi type, OF-02G-4C)

- Natural Convection Ovens (General, ON)

- Natural Convection Ovens (Economy)

- Muffle Furnace

- Pumps

- Refrigerators & Freezers

- Rotator

- Special Purpose Chamber

- Shaker

- Storage

- Fire Safety Storage Cabinet (Type 90)

- Fire Safety Storage Cabinet (Type 30)

- Acid / Corrosive Cabinets

- Molded Acid Corrosive Cabinet

- Multipurpose Cabinet (Window Type)

- Gas Cylinder Cabinets

- Laboratory Refrigerators

- Filtering Storage Cabinets

- Filtering Storage Refrigerator

- Laboratory Freezers

- Vacuum Desiccators (Cubic)

- Vacuum Desiccators (Round)

- Vacuum Desiccators (Cylindrical)

- Desiccators (Cubic Models)

- Temperature Chambers

- Heating & Cooling Chamber Tabletop type (TC3-ME)

- Heating & Cooling Chamber Tabletop type (TC3-KE)

- Forced Convection Ovens (Large- Programmable)

- Forced Convection Ovens (Large-General)

- Heating Chambers (LBV)

- Heating Chambers (LTV)

- Heating & Cooling Chambers (KBD)

- Heating & Cooling Chambers (KMV)

- Heating & Cooling Chambers (JMV)

- Heating & Cooling Chambers (PBV)

- Heating & Cooling Chambers (PMV)

- Heating & Cooling Chambers (LCH)

- Heating & Cooling Chambers (LCH-G)

- Plastic ware & Others

- Safety Waste Disposal System

- Handle Beaker (Transparent / Translucent)

- Wash Bottle

- Power Supply for Electrophoresis System

- Ultrasonic Cleaners

- Electrophoresis Systems

- Magnetic Drives

- Disposable Beaker

- Plastic Beakers

- Tubing Connectors

- Carboys

- Flask Supports

- On-Ice Rack

- Tube Rack

- Storage Boxes

- Cryo Boxes

- Clamp Holders

- Software

Vacuum Ovens

Optimally constructed for separatingsolvents from solutions or drying solvents with high boiling points.

Model Name : OV-11/12

Performance

- Temperature range from ambient +5°C to 250°C

- Vacuum range: 0 to 0.1 MPa. (analog vacuum gauge)

- Drying a solvent in vacuum lowers its boiling point, thereby making the separation process easier and eliminating the need to use high temperatures. - Microprocessor PID control / Temperature calibration / Automatic tuning.

- Uniform heat distribution from block type heater attached to the chamber exterior to the anodized aluminum shelves.

Convenience

- Intuitive control panel with bright LED displays. (1°Cresolution)

- Dual wait on/off timer modes. (1 min. to 99 hr. 59 min.)

- Convenient presetting function for 3 most commonly used temperature settings.

- Viton (fluorine rubber) door gasket also available for acidic applications. (optional)

- Heat tempered glass window provides clear inside view of the chambers

- Tight vacuum seal thanks to spring-loaded glass door, silicone gasket, and a push-button latch handle.

- Separate vacuum and vent ports.

- RS-232 interface for external control and data collection.

Safety

- Keypad lock function prevents accidental changes during operation.

- Automatic run after power interruption.

- Over-temperature and over-current protection.

| Model | OV-11 | OV-12 | |

|---|---|---|---|

| Chamber volume (L / cu ft) | 28 / 1 | 65 / 2.3 | |

| Vacuum range | 0~0.1MPa, Analog | ||

| Nozzle size (mm / inch) | Vacuum Ø10 / 0.4, Vent Ø10 / 0.4 | ||

| Temperature | Range (℃ / ℉) | Amb. +5 to 250 / Amb. +9 to 482 | |

| Fluctuation 1) (±℃ / ℉ at 100℃) | 0.1 / 0.18 | 0.3 / 0.54 | |

| Variation 1) (±℃ / ℉ at 100℃) | 5.0 / 9.0 | ||

| Dimension(W×D×H) | Interior (mm / inch) | 302×305×302 / 11.9×12×11.9 | 402×405×402 / 15.8×15.9×15.8 |

| Exterior (mm / inch) | 680×453×495 / 26.8×17.8×19.5 | 780×557×595 / 30.7×21.9×23.4 | |

| Net weight (Kg / lbs) | 63 / 139 | 103 / 227 | |

| Electrical requirements (230V, 50 / 60 Hz) | 5.3A | 6.1A | |

| Cat. No. | AAH13115K | AAH13125K | |

| Electrical requirements (120V, 50 / 60 Hz) | 10A | 11.7A | |

| Cat. No. | AAH13116U | AAH13126U | |

1) Technical data according to DIN 12880.

for Vacuum ovens

-

Safety covers

-

Viton gaskets

-

Vacuum pumps

-

Cold trap baths

Safety covers

In case of the glass is destroyed, the netted steel frame and polycarbonate sheet cover prevent user from glass splinters.

| Cat. No. | Description | Suitable for |

|---|---|---|

| AAA13603 | Safety cover | OV-11 |

| AAA13604 | Safety cover | OV-12 |

Gaskets

Viton (fluorine rubber) door gaskets can be provided upon request.

| Cat. No. | Description | Suitable for |

|---|---|---|

| 00FAA0005146 | Silicone gasket | OV-11 |

| 00FAA0005187 | Viton (fluorine rubber) gasket | |

| 00FAA0005147 | Silicone gasket | OV-12 |

| 00FAA0005188 | Viton (fluorine rubber) gasket |

Vacuum pumps

Rotary vacuum pumps with directly connected oil seal prevent air reflux and provide high vacuum pressure for vacuum ovens.

| Cat. No. | Description |

|---|---|

| BEH73205K | W2V10 (230V, 50/60Hz) |

| BEH73206U | W2V10 (120V, 60Hz) |

| BEA700351 | Oil mist trap (PC) |

| BEA700355 | Oil mist trap (metal) |

| BEA700353 | Vacuum pump oil (1L) |

| BEA700354 | Vacuum pump oil (20L) |

※ In order to get rid of evaporated oil or to block oil in-flow, an optional oil mist trap is recommended. (refer to page 107 for additional information.)

Cold trap baths

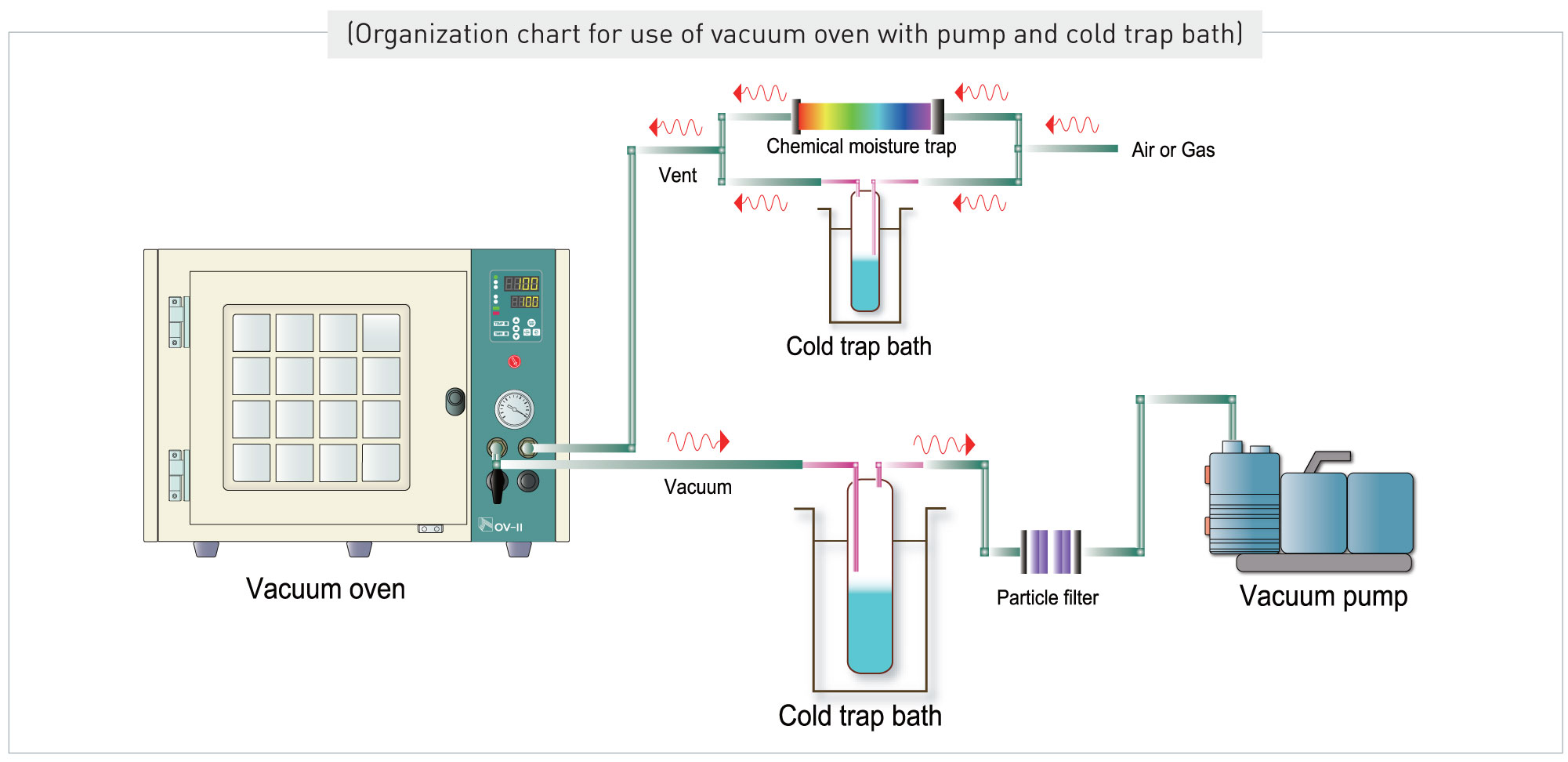

CTB-10 cold trap baths equipped with two U-type glass traps prevent a vacuum pump from vapors or contamination.

| Cat. No. | Description |

|---|---|

| AAH62011K | CTB-10 (230V, 60Hz) |

| AAH62012K | CTB-10 (230V, 50Hz) |

| 00FCA0001110 | U-type glass trap (1ea) |

Related products for vacuum ovens

※ In order to get rid of evaporated oil or to block oil in-flow, an optional oil mist trap is recommended. (refer to page 107 for additional information.)